B125Q/900_001

SQUARE

(test load 12.5 ton) Footways, pedestrian areas and comparable areas, car parking decks.

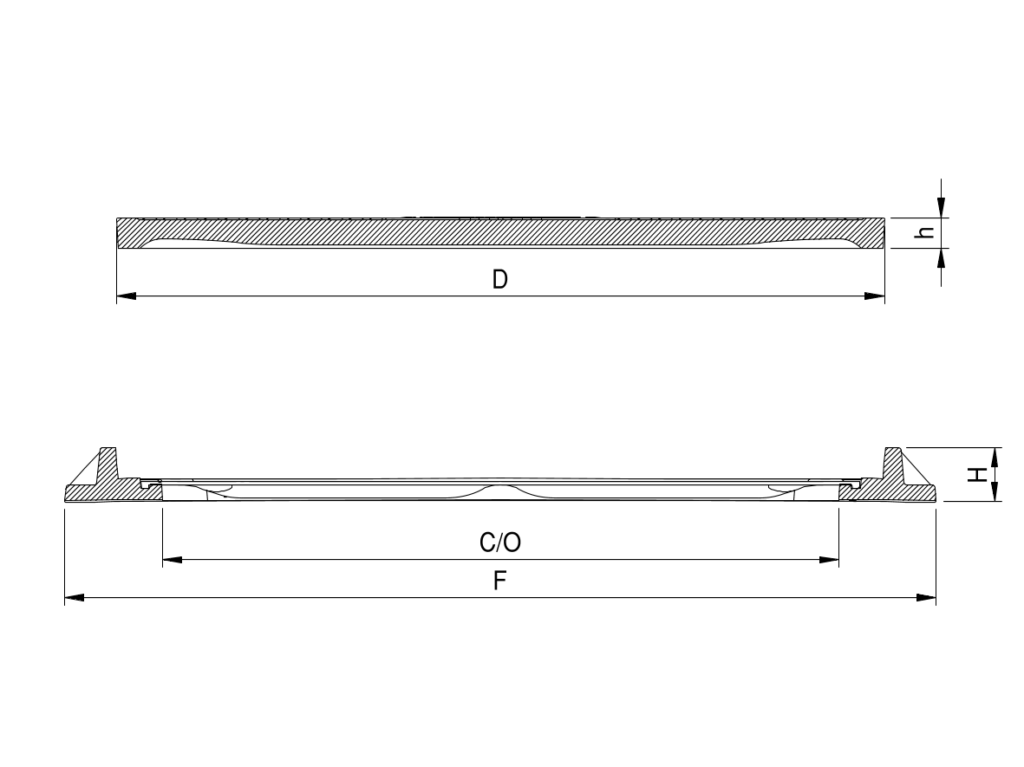

Cover

D

1000X1000 mm

h

40 mm

Frame

C/O

880X880 mm

F

1135X1135 mm

H

70 mm

Weight

Frame

28.4 kg

Cover

54.6 kg

Total

83 kg

Norm

EN 124-5:2015

Manufacturing process

SMC compression molding with prepregs

Surface design

14x14 square with T01 treatment

Colour

black RAL 9011

Fixing

4 screws TCE

Lifting

2 eye screws 2 washers 2 hexagonal nuts

Specification item

Manhole cover in composite material class B125, square shape, clear span 900x900 mm Supply of M.M. srl manhole cover for inspection chambers class B125 type B125Q/900_001, produced in COMPOSITE material (thermosetting resins, glass fibers and other additives) by means of a compression and (SMC) controlled temperature molding process, C2 class and in compliance with EN 124-5:2015 norm by ISO 9001:2015 certified company. Black color in mass, other colors as an option on request. Marking with class of resistance, norm reference, identification of the producer and quality mark issued by international accredited certification body. Name of buyer or optional service upon request. Composed of: - SQUARE shape frame in COMPOSITE material complete of specific wings for the perfect anchoring during installation. – SQUARE shape cover in COMPOSITE material with non-slip surface. Customized motives upon request. Locking system by means of S.S. screws, concealed lifting system made of S.S. eyelets and specific key included. C/O: 900x900 mm, F: 1035x1035 mm

Description and properties

Manhole covers and gully tops for use in vehicular and pedestrian areas. Design requirement, type testing, marking, quality control according to the UNI EN 124-5:2015 standard Certificate P187 issued by ICMQ. Reference norm (EN 124-5), producer identification and quality mark released by an internationally acknowledged certification authority; marked with resistance class.

Manufacturing process and material

For the EN 124-5:2015 norm requirement, the production of the manhole covers turns out to be of C2 class (”Composite material C2” Point 4.2 Type of composite materials). It’s a compression molding process made in a close mold with controlled temperature (SMC) by using thermosetting resin (polyester resin), glass fibers and other additives.